|

시장보고서

상품코드

1624581

고기능 동박 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)High-end Copper Foil - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

■ 보고서에 따라 최신 정보로 업데이트하여 보내드립니다. 배송일정은 문의해 주시기 바랍니다.

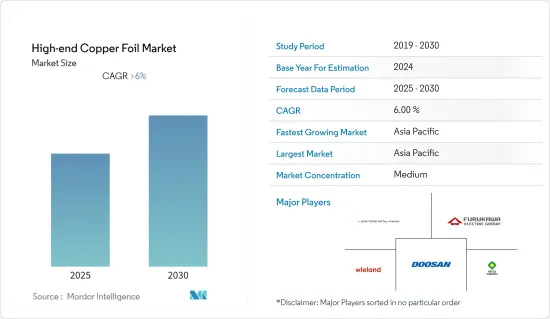

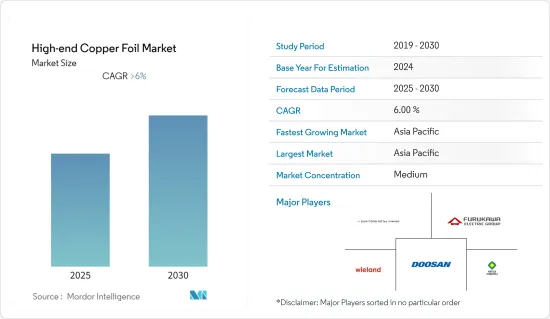

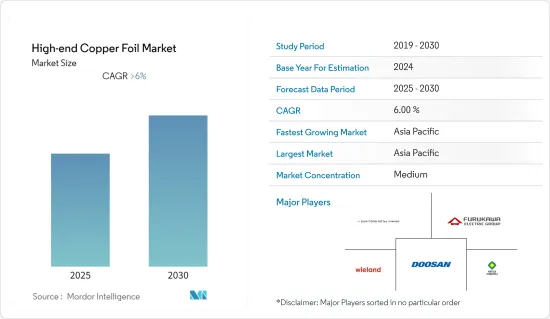

고기능 동박 시장은 예측 기간 동안 6% 이상의 CAGR을 나타낼 것으로 예상됩니다.

주요 하이라이트

- 회로기판 응용 분야가 시장을 주도하고 있으며, 스마트폰, PC, 태블릿 및 기타 의료용 전자제품과 같은 소비자 가전제품에 대한 수요 증가로 인해 예측 기간 동안 완만한 성장이 예상됩니다.

- 변압기 및 그리드 레벨의 에너지 저장에 사용되는 동박은 기회가 될 것으로 보입니다.

- 동박을 대체할 수 있는 단결정 그래핀 시트의 개발은 시장 성장을 저해할 것으로 예상됩니다.

- 아시아태평양이 세계 시장을 독점하고 있으며, 중국, 인도 등 국가들의 소비가 가장 큽니다.

고기능 동박 시장 동향

회로 기판 수요 증가

- 대부분의 전자 제품에는 인쇄 회로 기판(PCB)이 사용됩니다. 고품질 PCB 제조 기술을 통해 전자 제품 제조업체는 더 작고 복잡한 제품을 생산할 수 있게 되었습니다. 오늘날의 역동적이고 빠르게 발전하는 전자 기술 혁신의 열쇠를 쥐고 있습니다.

- 인쇄 회로 기판 제조에 사용되는 기판은 유리 섬유 강화 에폭시 수지 라미네이트입니다. 에폭시 수지에는 한쪽 또는 양면에 구리 호일이 접착되어 있습니다.

- 인쇄 회로 기판에 사용되는 동박은 주로 전해 동박과 압연 동박의 두 가지 유형이 있습니다. 두 가지 유형 모두 많은 변형이 있으며, 전해 동박이 가장 많은 선택을 받고 있습니다. 동박의 특성은 고주파 회로에 필수적입니다.

- 압연 동박은 매끄러운 표면이 선호되는 유연한 회로 기판에 널리 사용됩니다. 전해 동박은 경질 및 연성 회로에 사용됩니다.

- 스마트폰, PC, 태블릿 및 기타 의료용 전자제품과 같은 소비자 가전제품에 대한 수요가 전 세계적으로 급증하고 있으며, 인도와 중국이 계속해서 시장 성장의 선두를 차지할 것으로 예상됩니다. 인쇄 회로 기판은 거의 모든 전자 제품에 사용되고 있으며, 향후 몇 년동안 고품질 동박에 대한 수요가 증가할 것으로 예상됩니다.

- 전 세계에는 2687 개의 PCB 공장이 있으며 중국은 그 중 55%를 차지하고 있으며, 2020년이후 구리 클래드 라미네이트를 포함한 모든 PCB 재료의 가격이 상승했지만 PCB 가격 상승은 그다지 급격하지 않습니다. 따라서 중국의 PCB 부문은 점점 더 수익성이 떨어지고 있습니다. 수익성이 낮은 PCB 부문은 잉여 생산 능력을 줄임으로써 전력 절감의 혜택을 누릴 수 있습니다.

- 정부가 PCB 공장에 막대한 인센티브를 제공하기 때문에 PCB의 51% 이상이 중국에서 제조됩니다. 중국은 또한 이러한 회로 기판을 적은 비용으로 생산하고 있습니다. 그 결과 전 세계의 많은 기업들이 사업을 폐쇄하고 있습니다.

- 영국에는 지난 10년간 300개 이상의 PCB 공장이 있었으나 현재는 35개 이하로 감소했습니다. 남아프리카공화국도 원자재 및 인건비 증가로 인해 동일한 영향을 받고 있습니다.

- IPC에 따르면 2022년 11월 북미 PCB 출하량은 전년 동월 대비 26.1% 증가했으며, 11월 출하량은 전월 대비 13.1% 증가했습니다.

- 이러한 모든 요인들이 향후 몇 년동안 고급 구리 시장을 주도할 것으로 보입니다.

아시아태평양이 시장을 지배합니다.

- 아시아태평양은 중국과 인도를 포함한 국가들의 생산 활동 증가로 인해 세계 시장 점유율을 독식했습니다.

- 정부가 PCB 공장에 막대한 인센티브를 제공하고 있기 때문에 PCB의 50% 이상이 중국에서 생산되고 있습니다.

- India Energy Storage Alliance(IESA)에 따르면 인도의 EV 시장은 연평균 36%의 성장률을 보일 것이라고 합니다. 인도 중공업부에 따르면 지난 3년간 인도에서 52만 대의 EV가 등록되었으며, 정부의 유익한 법률 및 이니셔티브 채택에 힘입어 2021년에 EV는 강력한 성장을 이룰 것으로 예상됩니다.

- e-2W 사용을 촉진하기 위해 FAME-II 제도는 수요 장려금을 INR10,000/KWh(122.60 USD/KWh)에서 INR15,000/KWh(183.90 USD/KWh)로 인상하여 차량 비용의 20%에서 거의 40%로 상향 조정했습니다. 증가했습니다. 또한, FAME-India 제도의 2단계는 2022년 3월 31일부터 2년 더 연장되었습니다. 이는 예측 기간 동안 연구 시장의 성장을 가속할 것으로 보입니다.

- 현재 인도의 PCB 수요의 35%는 국내 생산으로 충당하고 나머지 65%는 수입에 의존하고 있습니다. 인도는 현재 인구 PCB와 베어 PCB를 모두 생산하고 있습니다. 후자의 현재 시장 규모는 약 12억 달러이며 그 중 30%가 인도에서 생산됩니다.

- 한국의 PCB 제조업체는 높은 기술력을 보유하고 있어 고기능 동박 시장에 이익을 가져다 줄 것으로 보입니다. 이들 업체들은 애플로부터 PCB를 수주하고 있으며, TAESUNG은 애플용 PCB를 생산하는 주요 업체입니다.

- KPCA(Korean Printed Circuits Association)에 따르면 한국은 인쇄 회로 기판 시장의 13%를 차지하고 있으며 이는 중국(49%), 대만(12%), 일본(8%)에 이어 세계 2 위를 차지했습니다.

- 이러한 요인들은 정부의 지원과 함께 예측 기간 동안 이 지역의 고기능 동박 소비 수요 증가에 기여하고 있습니다.

고기능 동박 산업 개요

고기능 동박 시장은 부분적으로 통합되어 있으며, 주요 5개 기업이 시장의 상당 부분을 점유하고 있습니다. 주요 기업으로는(순서대로) Mitsui Mining & Smelting, Furukawa Electric, Sumitomo Metal Mining, Doosan Corporation, Wieland Group 등이 있습니다.

기타 혜택 :

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 지원

목차

제1장 서론

- 조사의 전제조건

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 성장 촉진요인

- 성장 억제요인

- 밸류체인 분석

- Porter의 Five Forces 분석

- 공급 기업의 교섭력

- 소비자의 교섭력

- 신규 진출업체의 위협

- 대체품의 위협

- 경쟁 정도

제5장 시장 세분화

- 유형별

- 압연 동박

- 전해 동박

- 용도별

- 회로 기판

- 배터리

- 솔라 및 대체 에너지

- 가전제품

- 의료용

- 기타 용도

- 지역별

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주 및 뉴질랜드

- 기타 아시아태평양

- 북미

- 미국

- 캐나다

- 멕시코

- 유럽

- 독일

- 영국

- 이탈리아

- 프랑스

- 러시아

- 기타 유럽

- 남미

- 브라질

- 아르헨티나

- 기타 남미

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카공화국

- 기타 중동 및 아프리카

제6장 경쟁 구도

- 인수합병(M&A)/합작투자(JV)/협업/협정

- 시장 순위 분석

- 주요 기업의 전략

- 기업 개요

- Chang Chun Petrochemical Co. Ltd

- Civen Metal Material(Shanghai) Co. Ltd

- Doosan Corporation

- Fukuda Metal Foil & Powder Co. Ltd

- JX Nippon Mining & Metals Corporation

- Mitsui Mining & Smelting Co. Ltd

- Solus Advanced Materials

- Sumitomo Metal Mining Co. Ltd

- SH Copper Products Co. Ltd

- The Furukawa Electric Co. Ltd

- Targray Technology International Inc.

- UACJ Foil Corporation

- Wieland Group

제7장 시장 기회와 향후 동향

- 변압기와 그리드 레벨 에너지 저장 동박

LSH 25.01.15

The High-end Copper Foil Market is expected to register a CAGR of greater than 6% during the forecast period.

Key Highlights

- Circuit board applications dominate the market and are expected to grow at a moderate rate during the forecast period, owing to the increasing demand for consumer gadgets like smartphones, PCs, tablets, and other medical electronics products.

- Copper foils in transformer and grid-level energy storage are likely an opportunity.

- The development of single-crystal graphene sheets as a substitute for copper foil is expected to hinder the market's growth.

- Asia-Pacific dominated the market across the world, with the most significant consumption from countries such as China and India.

High-End Copper Foil Market Trends

Increasing Demand for Circuit Boards

- Most of the electronics products manufactured contain printed circuit boards (PCBs). High-quality PCB manufacturing technology allowed electronics product manufacturers to produce smaller, more complex products. It is the key to today's dynamic and rapidly progressing electronic innovations.

- The substrate used to manufacture printed circuit boards is fiberglass-reinforced epoxy laminate. Epoxy resin includes a copper foil bonded to one or both sides.

- Two main types of copper foil are used in PCBs: electrodeposited and rolled copper foil. Both these types have many possible variations, with the most choices available for ED copper. Copper foil characteristics are essential for high-frequency circuits.

- Rolled copper foil is used extensively for flexible circuit boards where a smooth surface is preferred. Electrodeposited copper foils are used in rigid, flexible circuits.

- The demand for consumer gadgets, such as smartphones, PCs, tablets, and other medical electronics products, is rapidly increasing globally, with India and China expected to remain at the top of market growth. As printed circuit boards are deployed in almost all electronics products, it will likely drive the demand for high-quality copper foil in the coming years.

- There are 2687 PCB plants worldwide, with China having 55%. Since 2020, the prices of all PCB materials, including copper-clad laminates, have been growing, while PCB prices have increased less sharply. It made the PCB sector in China increasingly unprofitable. The low-profit PCB sector may benefit from power cutbacks by reducing the surplus capacity.

- Over 51% of the PCBs are manufactured in China, owing to the offering of huge incentives by the government to the PCB factories. China is also producing these circuit boards at a meager cost. As a result, many companies across the world are closing their operations.

- The United Kingdom used to have over 300 PCB factories over the last decade, but it is now reduced to less than 35. South Africa is also experiencing the same effects due to increased raw materials and labor costs.

- According to IPC, PCB shipments from North America increased by 26.1% while comparing November 2022 to the same month in the previous year. Shipments in November increased by 13.1% over the last month.

- All the above factors are expected to drive the market for high-end copper in the coming years.

Asia-Pacific Region to Dominate the Market

- The Asia-Pacific region dominated the global market share due to the increasing production activities in countries, including China and India.

- More than 50% of PCBs are manufactured in China, owing to the huge incentives offered by the government to PCB factories.

- According to the India Energy Storage Alliance (IESA), the Indian EV market would grow at a CAGR of 36%. According to the Ministry of Heavy Industries, 0.52 million EVs have been registered in India during the previous three years. EVs had strong growth in 2021, aided by the government's adoption of beneficial laws and initiatives.

- For encouraging e-2W use, the demand incentive raised under the FAME-II scheme from INR 10,000/KWh (USD 122.60/KWh) to INR 15,000/KWh (183.90/KWh), with a cap rise from 20% to almost 40% of vehicle cost. Additionally, the FAME-India Scheme's Phase II was extended for an additional two years beginning on March 31, 2022. It would, in turn, promote the growth of the studied market during the forecast period.

- Currently, 35% of India's PCB need is met by domestic production while being dependent on imports for the remaining 65%. India presently produces both populated and bare PCBs. The current market size for the latter is around US$ 1.2 billion, with 30% of that market's production occurring in India.

- The PCB manufacturers in South Korea have advanced technical skills, which will likely benefit the high-end copper foil market. These manufacturers have won orders for PCB from Apple. TAESUNG is the leading company dealing with PCB for Apple manufacturing.

- According to KPCA (Korean Printed Circuits Association), South Korea occupies 13% of the PCB market, which is the second largest in the world behind China (49%), followed by Taiwan (12%) and Japan (8%).

- The factors above, coupled with government support, contribute to the increasing demand for high-end copper foil consumption in the region during the forecast period.

High-End Copper Foil Industry Overview

The high-end copper foil market is partially consolidated, with the top five players accounting for a considerable chunk of the market. The major companies include (not in any particular order) Mitsui Mining & Smelting Co. Ltd, Furukawa Electric Co. Ltd, Sumitomo Metal Mining Co. Ltd, Doosan Corporation, and Wieland Group, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Application as a Printed Circuit Board (PCB) Material

- 4.1.2 Increasing Demand for Lithium Ion Batteries From Transportation and Energy Storage Sector

- 4.2 Restraints

- 4.2.1 Development of Single Crystal Graphene Sheet as a Substitute for Copper Foil

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Rolled Copper Foil

- 5.1.2 Electrodeposited (ED) Copper Foil

- 5.2 Application

- 5.2.1 Circuit Boards

- 5.2.2 Batteries

- 5.2.3 Solar and Alternative Energy

- 5.2.4 Appliances

- 5.2.5 Medical

- 5.2.6 Other Applications

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Australia & New Zealand

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Russia

- 5.3.3.6 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Chang Chun Petrochemical Co. Ltd

- 6.4.2 Civen Metal Material(Shanghai) Co. Ltd

- 6.4.3 Doosan Corporation

- 6.4.4 Fukuda Metal Foil & Powder Co. Ltd

- 6.4.5 JX Nippon Mining & Metals Corporation

- 6.4.6 Mitsui Mining & Smelting Co. Ltd

- 6.4.7 Solus Advanced Materials

- 6.4.8 Sumitomo Metal Mining Co. Ltd

- 6.4.9 SH Copper Products Co. Ltd

- 6.4.10 The Furukawa Electric Co. Ltd

- 6.4.11 Targray Technology International Inc.

- 6.4.12 UACJ Foil Corporation

- 6.4.13 Wieland Group

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Copper Foils In Transformer and Grid-level Energy Storage

- 공급 기업의 교섭력

- 소비자의 교섭력

- 신규 진출업체의 위협

- 대체품의 위협

- 경쟁 정도

- 압연 동박

- 전해 동박

- 회로 기판

- 배터리

- 솔라 및 대체 에너지

- 가전제품

- 의료용

- 기타 용도

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주 및 뉴질랜드

- 기타 아시아태평양

- 북미

- 미국

- 캐나다

- 멕시코

- 유럽

- 독일

- 영국

- 이탈리아

- 프랑스

- 러시아

- 기타 유럽

- 남미

- 브라질

- 아르헨티나

- 기타 남미

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카공화국

- 기타 중동 및 아프리카

- Chang Chun Petrochemical Co. Ltd

- Civen Metal Material(Shanghai) Co. Ltd

- Doosan Corporation

- Fukuda Metal Foil & Powder Co. Ltd

- JX Nippon Mining & Metals Corporation

- Mitsui Mining & Smelting Co. Ltd

- Solus Advanced Materials

- Sumitomo Metal Mining Co. Ltd

- SH Copper Products Co. Ltd

- The Furukawa Electric Co. Ltd

- Targray Technology International Inc.

- UACJ Foil Corporation

- Wieland Group

The High-end Copper Foil Market is expected to register a CAGR of greater than 6% during the forecast period.

Key Highlights

- Circuit board applications dominate the market and are expected to grow at a moderate rate during the forecast period, owing to the increasing demand for consumer gadgets like smartphones, PCs, tablets, and other medical electronics products.

- Copper foils in transformer and grid-level energy storage are likely an opportunity.

- The development of single-crystal graphene sheets as a substitute for copper foil is expected to hinder the market's growth.

- Asia-Pacific dominated the market across the world, with the most significant consumption from countries such as China and India.

High-End Copper Foil Market Trends

Increasing Demand for Circuit Boards

- Most of the electronics products manufactured contain printed circuit boards (PCBs). High-quality PCB manufacturing technology allowed electronics product manufacturers to produce smaller, more complex products. It is the key to today's dynamic and rapidly progressing electronic innovations.

- The substrate used to manufacture printed circuit boards is fiberglass-reinforced epoxy laminate. Epoxy resin includes a copper foil bonded to one or both sides.

- Two main types of copper foil are used in PCBs: electrodeposited and rolled copper foil. Both these types have many possible variations, with the most choices available for ED copper. Copper foil characteristics are essential for high-frequency circuits.

- Rolled copper foil is used extensively for flexible circuit boards where a smooth surface is preferred. Electrodeposited copper foils are used in rigid, flexible circuits.

- The demand for consumer gadgets, such as smartphones, PCs, tablets, and other medical electronics products, is rapidly increasing globally, with India and China expected to remain at the top of market growth. As printed circuit boards are deployed in almost all electronics products, it will likely drive the demand for high-quality copper foil in the coming years.

- There are 2687 PCB plants worldwide, with China having 55%. Since 2020, the prices of all PCB materials, including copper-clad laminates, have been growing, while PCB prices have increased less sharply. It made the PCB sector in China increasingly unprofitable. The low-profit PCB sector may benefit from power cutbacks by reducing the surplus capacity.

- Over 51% of the PCBs are manufactured in China, owing to the offering of huge incentives by the government to the PCB factories. China is also producing these circuit boards at a meager cost. As a result, many companies across the world are closing their operations.

- The United Kingdom used to have over 300 PCB factories over the last decade, but it is now reduced to less than 35. South Africa is also experiencing the same effects due to increased raw materials and labor costs.

- According to IPC, PCB shipments from North America increased by 26.1% while comparing November 2022 to the same month in the previous year. Shipments in November increased by 13.1% over the last month.

- All the above factors are expected to drive the market for high-end copper in the coming years.

Asia-Pacific Region to Dominate the Market

- The Asia-Pacific region dominated the global market share due to the increasing production activities in countries, including China and India.

- More than 50% of PCBs are manufactured in China, owing to the huge incentives offered by the government to PCB factories.

- According to the India Energy Storage Alliance (IESA), the Indian EV market would grow at a CAGR of 36%. According to the Ministry of Heavy Industries, 0.52 million EVs have been registered in India during the previous three years. EVs had strong growth in 2021, aided by the government's adoption of beneficial laws and initiatives.

- For encouraging e-2W use, the demand incentive raised under the FAME-II scheme from INR 10,000/KWh (USD 122.60/KWh) to INR 15,000/KWh (183.90/KWh), with a cap rise from 20% to almost 40% of vehicle cost. Additionally, the FAME-India Scheme's Phase II was extended for an additional two years beginning on March 31, 2022. It would, in turn, promote the growth of the studied market during the forecast period.

- Currently, 35% of India's PCB need is met by domestic production while being dependent on imports for the remaining 65%. India presently produces both populated and bare PCBs. The current market size for the latter is around US$ 1.2 billion, with 30% of that market's production occurring in India.

- The PCB manufacturers in South Korea have advanced technical skills, which will likely benefit the high-end copper foil market. These manufacturers have won orders for PCB from Apple. TAESUNG is the leading company dealing with PCB for Apple manufacturing.

- According to KPCA (Korean Printed Circuits Association), South Korea occupies 13% of the PCB market, which is the second largest in the world behind China (49%), followed by Taiwan (12%) and Japan (8%).

- The factors above, coupled with government support, contribute to the increasing demand for high-end copper foil consumption in the region during the forecast period.

High-End Copper Foil Industry Overview

The high-end copper foil market is partially consolidated, with the top five players accounting for a considerable chunk of the market. The major companies include (not in any particular order) Mitsui Mining & Smelting Co. Ltd, Furukawa Electric Co. Ltd, Sumitomo Metal Mining Co. Ltd, Doosan Corporation, and Wieland Group, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Application as a Printed Circuit Board (PCB) Material

- 4.1.2 Increasing Demand for Lithium Ion Batteries From Transportation and Energy Storage Sector

- 4.2 Restraints

- 4.2.1 Development of Single Crystal Graphene Sheet as a Substitute for Copper Foil

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Rolled Copper Foil

- 5.1.2 Electrodeposited (ED) Copper Foil

- 5.2 Application

- 5.2.1 Circuit Boards

- 5.2.2 Batteries

- 5.2.3 Solar and Alternative Energy

- 5.2.4 Appliances

- 5.2.5 Medical

- 5.2.6 Other Applications

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Australia & New Zealand

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Russia

- 5.3.3.6 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Chang Chun Petrochemical Co. Ltd

- 6.4.2 Civen Metal Material(Shanghai) Co. Ltd

- 6.4.3 Doosan Corporation

- 6.4.4 Fukuda Metal Foil & Powder Co. Ltd

- 6.4.5 JX Nippon Mining & Metals Corporation

- 6.4.6 Mitsui Mining & Smelting Co. Ltd

- 6.4.7 Solus Advanced Materials

- 6.4.8 Sumitomo Metal Mining Co. Ltd

- 6.4.9 SH Copper Products Co. Ltd

- 6.4.10 The Furukawa Electric Co. Ltd

- 6.4.11 Targray Technology International Inc.

- 6.4.12 UACJ Foil Corporation

- 6.4.13 Wieland Group

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Copper Foils In Transformer and Grid-level Energy Storage

비교리스트